Our History

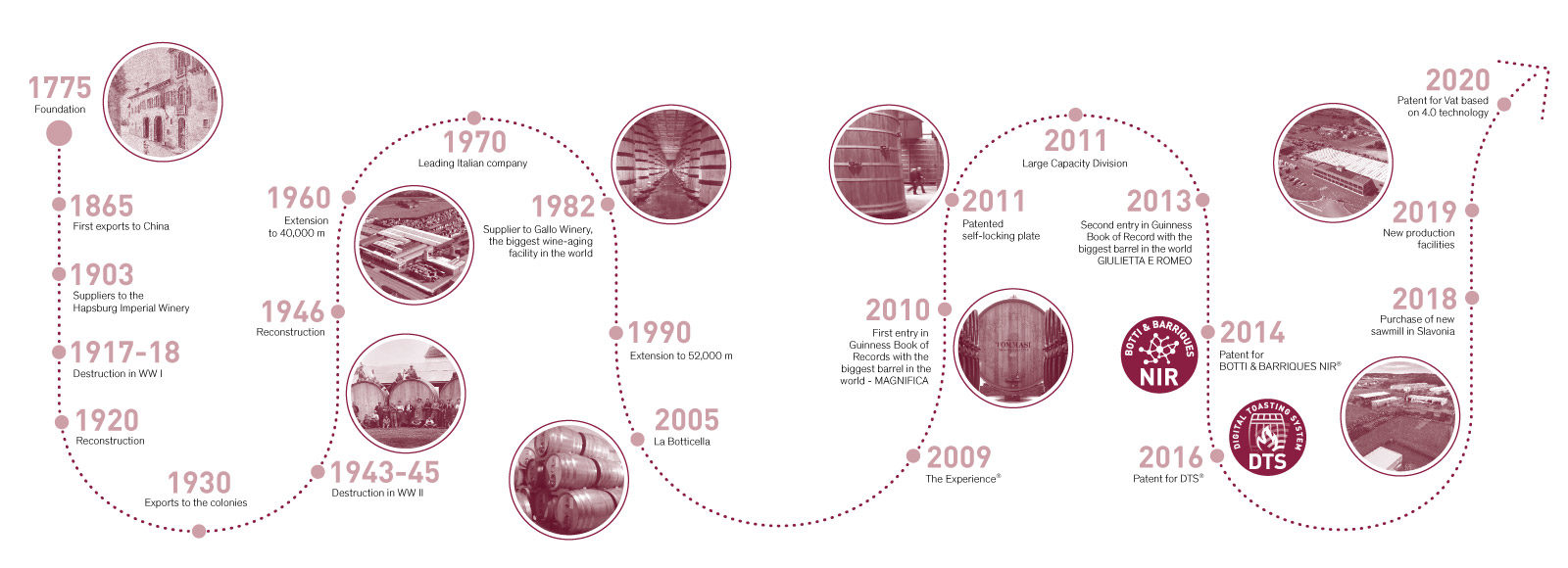

The Garbellotto story began in 1775 when Giuseppe Garbellotto opened a carpenter’s workshop, where he also produced wine casks and barrels. He eventually passed the firm on to his son Pietro, and nephew Augusto Emilio.

Business flourished throughout the 1800s, so much so that Karl of Hapsburg, the last Emperor of Austria, commissioned Garbellotto to renovate the wine cellar of his wife, Empress Zita of Bourbon-Parma.

The company prospered in its first location at San Fior, now the family residence, until World War I, when production ceased following occupation by Austrian troops. The building was converted into a military first aid post and all the archives were destroyed; only a few pieces of furniture and some documents survived.

After the war, Giobatta Garbellotto, grandfather of the current owners, transferred the company to Conegliano, where he organised it to new industrial criteria, laying the foundations for future success. During the period between the two wars the business supplied the first cooperative wineries and sent its first exports to the colonies, but Europe was in the throes of the turmoil that led to World War II, during which the company premises were destroyed. At the end of the war, Pietro and his father Giobatta purchased land flanking the Conegliano by-pass, and built new facilities.

In the sixties and seventies many wineries throughout Italy had to start from scratch and coopers travelled the peninsula to position, mount and test in situ products such as Biondi Santi, Bertani and Kiola medium-sized casks and large distillation vats for important groups such as Branca, Montenegro and Stock.

The company still had a prevalently artisan connotation, but Pietro’s preoccupation was the purchase of timber. He stepped up his journeys in Europe, where he selected the best oak timber, to be sawn in-house at Conegliano. At this point he had decided to add a sawmill to his cooper’s business and sell the wood whose aroma was not suitable for wine. In this way, he was able to purchase large lots of oak timber at bargain prices, reducing his costs and keeping quality high, earning his products the definition of the Rolls Royce of barrels and taking his company to a leading position in Italy.

His business would be mentioned in several books, including by Mario Soldati and Giovanni Comisso, and a visit to the facilities became a must for the students of many Oenology Schools.

The timber trade was fundamental in saving the business in the early 80s, the years of the oil crisis, when consumers changed their drinking tastes, preferring young wines to aged ones, which greatly stressed the industry.

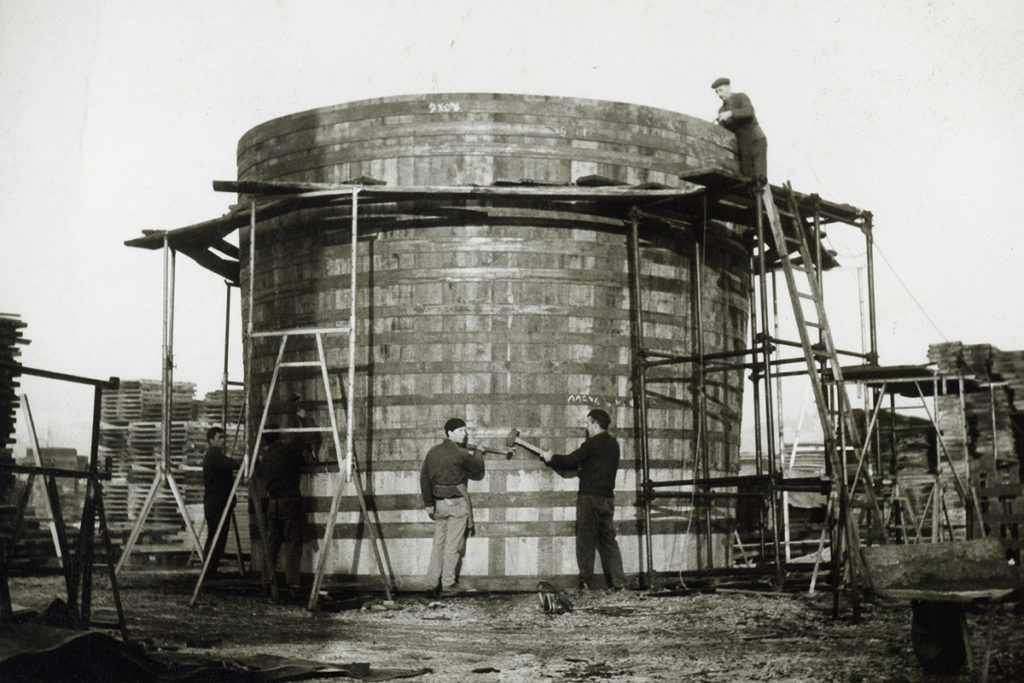

However, recovery was quick: in the USA the Gallo family was preparing to build one of the biggest wine-aging facilities in the world, with 712 x 166 hl vats. This huge order carried business through for a few years and the coopers were happy to light their fires and wield their hammers again.

Pietro, who had already received a knighthood, was named Grand Officer of the Order of Merit of the Republic. He passed away in 2011 at the age of 88, having already placed the business in his sons’ hands. The company developed in these years, when La Botticella®, the link between casks and oak barrels, was successfully launched onto the market, together with The Experience®, a 1,000 litre, self-emptying vat, ideal for fermenting small batches of grapes. The latest generation of Garbellotto coopers have had the satisfaction of two mentions in the Guinness Book of Records for the biggest barrels in the world.

The Large Capacity Division was inaugurated in 2011, where the company’s patented self-locking plate is used for the economical manufacture of large containers that can be assembled in situ. This division supplied the Acetum group with 80 x 800 hl and 40 x 400 hl vats, plus one – Hercules – for 2,700 hl.

In 2013, acknowledging its restricted capacity for research, the company began to cooperate with Udine University, working with professors Zironi and Battistutta, a collaboration still active today. This gave rise to patenting Botti & Barriques NIR® for aromatic selection and the Digital Toasting System® for digital control of toasting, to release ever more delicate, homogeneous nuances.

Given that its business is founded on timber, particularly oak wood, for some years now the company has been FSC® and PEFC certified. Whereas relationships in France were consolidated with several suppliers of oak timber, Croatia issued a law that prohibits the sale of fresh Slavonian Oak to companies outside the country’s borders.

To guarantee its supplies, Garbellotto acquired a 27,000m2 sawmill in Slavonia, with a State concession to fell oak trees. This branch would soon become the cutting and splitting centre for all Garbellotto’s timber, as it could take advantage of the ‘Baltic-Adriatic corridor’ to collect not only local Slavonian oak, but also oak timber from French and German forests.

Such re-organisation made it possible to build new premises, concentrating on the production of oak barrels and casks with wood selected in the forest by our own experts. In 2019 new facilities based on the 4.0 industrial plan and designed to the lean criteria of ‘Artisan Intelligence’ were opened.

The Industry 4.0 plan allows for hyper-amortisation and has led to our digitally controlled vats (patent applied for), a wooden vat with automatic temperature control that is eligible for tax benefits.