Vats

We make 10 hl to 250 hl truncated cone vats for vinification, storage and ageing of wine, spirits and vinegar, and on demand can provide vats with a capacity of 2,500 hl or over. We use the direct heat method known as ‘Bombè’ to slightly curve our vats. This helps the hoops to stay perfectly tightened. Unless otherwise specified, the ‘Bombè’ process is followed by DTS® digital toasting.

The construction process is completed by fitting hoops in prime quality, hot galvanised and phosphate-coated iron over the staves. The interior of each vat is lightly planed to facilitate cleaning in the winery, whereas the exterior is planed and then sanded.

All our vats are tested at controlled pressure and temperature to verify perfect seal and precise capacity. The process is completed by applying natural, breathable varnish and the appropriate accessories according to the type of vat: for fermentation, storage/ ageing, or industrial uses.

We have patented a wooden vat that manages fermentation through an app and is eligible for 4.0 hyper amortisation.

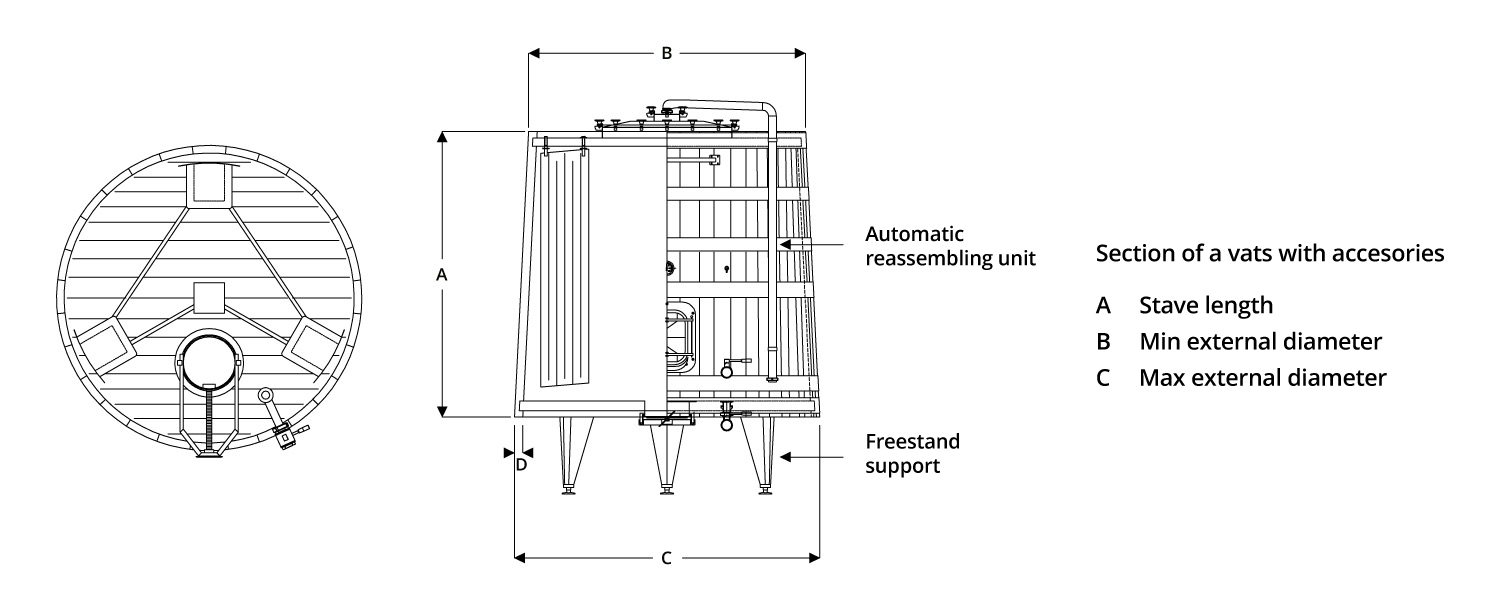

Section of vat with accessories

Accessories

Standard Accessories:

- diameter 40/120cm top cover in 18/10 AISI 316 stainless steel, available in two versions: with central bung hole and relative filling funnel or with diameter 22cm discharge pipe complete with double acting overpressure valve;

- stainless steel, outward opening door fitted close to or flush with the bottom of the vat;

- stainless steel partial discharge valve and full discharge unit, complete with required measuring valve and connection;

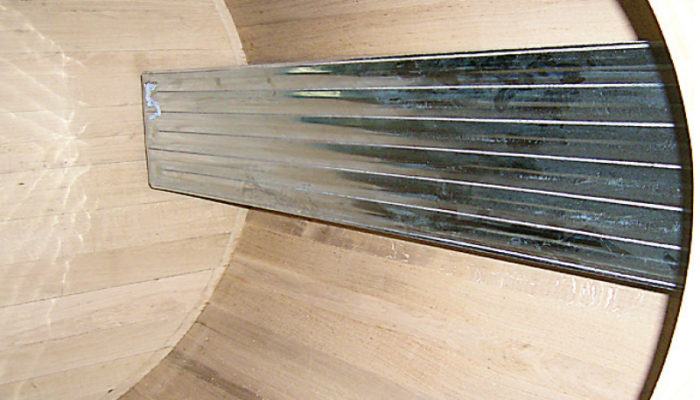

- thermal conditioning unit with mirror polished stainless steel plates, dimensions in proportion to the vat in question;

- digital or mechanical thermometer and approved steel ladder rest;

- suitable wooden supports, measuring 30cm from the ground.

Special Accessories on request:

- tubes for ‘delestage’;

- self-supporting stainless steel supports, measuring 60cm from the ground;

- automatic pumping over or cap punching down units;

- stainless steel shutter at the base of the vat for easy, complete discharge of pomace.

On request we can build simpler and much less costly open vats, either conical trunk or vase-shape, usable only for small amounts at the fermentation stage of wine-making. We also build tubs for saunas or private use with “neutral” wood species that do not interfer with water, such as larch and maple, etc.